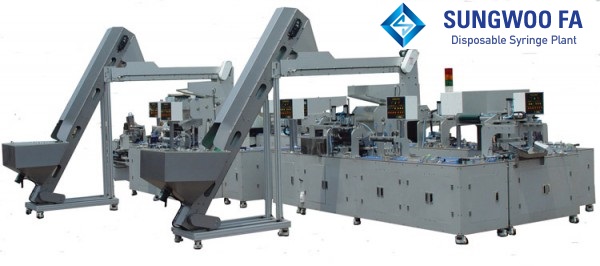

INSULIN ASSEMBLY LINE

페이지 정보

작성자 manager 댓글 0건 조회 9,740회 작성일 14-09-03 16:02본문

1. ORGANIZATION OF MACHINE

1) BARREL PRINTING MACHINE(MODEL : AK-INP)

2) PLUNGER & GASKET ASSEMBLY MACHINE(MODEL : AK-ING)

3) MAIN ASSEMBLY LINE(MODEL : AK-INM)

2. DIMENSION OF MACHINE

1) BARREL PRINTING MACHINE: 2020L x 2260W x 2300H

2) PLUNGER & GASKET ASSEMBLY MACHINE: 2300L x 200W x 1950H

3) MAIN ASSEMBLY LINE: 12,545L x 3900W x 2500H

3. WEIGHT : ABOUT 4500KG

4. ELECTRIC POWER : AC 3P 220/380V

5. ELECTRIC POWER CONSUMPTION : 20KW

6. AIR PRESSURE : 6Kg/㎠

7. AIR CONSUMPTION : 1200 ~ 1300L/Min

8. PRODUCT CAPACITY

1) BARREL PRINTING MACHINE: 18,000 ~ 20,000PCS/HOUR

2) PLUNGER & GASKET ASSEMBLY MACHINE: 18,000 ~ 20,000PCS/HOUR

3) MAIN ASSEMBLY LINE: 18,000 ~ 20,000PCS/HOUR

9. NUMBER OF WORKER

1) BARREL PRINTING MACHINE: 1PERSON

2) PLUNGER & GASKET ASSEMBLY MACHINE: 1PERSON

3) MAIN ASSEMBLY LINE: 4PERSONS

10. SPECIFICATION

1) BARREL PRINTING MACHINE

A. DEMENSION OF MACHINE : 2020 x 2260 x 2300 (L x W x H)

B. WEIGHT : ABOUT 500Kg

C. ELECTRIC POWER : AC 220V

D. ELECTRIC POWER CONSUMPTION : 2.0Kw

E. AIR PRESSURE : 6Kg/cm2 , 150L/Min

F. PRODUCT CAPACITY : 18,000 ~ 20,000PCS/HOUR

G. MAIN MOTOR : D.C Motor 1HP

H. INK SUPPLY TYPE : PUMP TYPE

I. BARREL SUPPLY TYPE : CENTRIFUGAL FEEDER, LINEAR FEEDER

J. PRINTING TYPE : ROTARY TYPE PRINTING

K. NUMBER OF WORKER : 1PERSON

2) PLUNGER & GASKET ASSEMBLY MACHINE

A. DEMENSION OF MACHINE: 2300 x 2000 x 1950 (L x W x H)

B. WEIGHT : ABOUT 400Kg

C. ELECTRIC POWER: AC 220V

D. ELECTRIC POWER CONSUMPTION: 2.0Kw

E. AIR PRESSURE: 6Kg/cm2 , 150L/Min

F. PRODUCT CAPACITY : 18,000~ 20,000PCS/HOUR

G. MAIN MOTOR : D.C Motor 1HP

H. GASKET SUPPLY TYPE : BOWL FEEDER, LINEAR FEEDER

I. PLUNGER SUPPLY TYPE : BOWL FEEDER, LINEAR FEEDER

J. ASSEMBLY TYPE : ROTARY ASSEMBLY

K. NUMBER OF WORKER : 1PERSON

3) MAIN ASSEMBLY LINE

A. DEMENSION OF MACHINE: 12,545 x 3,900 x 2,500 (L x W x H)

B. WEIGHT: ABOUT 3200KG

C. ELECTRIC POWER: AC 3P 220/380V

D. ELECTRIC POWER CONSUMPTION : 16KW

E. AIR PRESSURE: 6Kg/cm2 , 850L/Min

F. PRODUCT CAPACITY: 18,000 ~ 20,000PCS/HOUR

G. NOMBER OF WORKER : 4PERSONS

H. MAIN FRAME : AL6061

I. ZIG SIZE : 33 PIN

J. SPECIFICATION OF PART

a. BARREL SUPPLY SUPPLY TYPE : SHUT TYPE SHUT DRIVING : VIBRATOR 1/8HP METHOD OF BARREL IN ZIG : VACCUM FIXED AFTER PUSHING

b. ELECTRIC DISCHARGE TREATMENT 20000~25000V( Transformer)

c. CANNULA ASSEMBLY PART CANNULA SUPPLY TYPE : LIFT TYPE

d. BONDING PART U.V BONDING BONDING TYPE : WHEEL TYPE DRIVING MOTOR : SERVO CONTROL

e. DRYING TURNNEL U.V DRYING

f. POINT INSPECTION

g. SILICON COATING PART SILICON COATING TYPE : DIP TYPE

h. NEEDLE CAP ASSEMBLY PART SUPPLY TYPE : SHUT TYPE SHUT DRIVING : VIBRATOR 1/8HP METHOD OF BARREL IN ZIG : GUIDE IN PUSHING

i. EJECT & CHANGE ZIG

j. SILICON SPRAY METHOD OF SILICON SPRAY :NOZZLE IN INSIDE BARREL---SILICON SPRAY SILICON PUMP : MAGNETIC PUMP

k. PLUNGER ASSEMBLY PART SUPPLY TYPE : SHUT TYPE SHUT DRIVING : VIBRATOR 1/8HP METHOD OF PLUNGER ASSEMBLY : GUIDE IN PUSHING M. EJECTION OF BAD INSULIN UNIT BAD INSULIN : AUTO EJECT N. UPPER CAP ASSEMBLY PART SUPPLY TYPE : SHUT TYPE SHUT DRIVING : VIBRATOR 1/8HP METHOD OF UPPER CAP ASSEMBLY : GUIDE IN PUSHING O. PRODUCT EJECTOR

첨부파일

- INSULIN ASSEMBLY LINE_03.pdf (357.0K) 25회 다운로드 | DATE : 2019-01-25 11:33:36

댓글목록

등록된 댓글이 없습니다.